Laboratory training is not just professional development: it is a fundamental part of safety.

In research institutes and scientific laboratories, every procedure must be executed with absolute precision. A single mistake can put people, results, and entire projects at risk. But how can truly effective, hands-on, and above all safe training be ensured, without exposing operators and researchers to real hazards?

Today, more and more research centers recognize the limitations of traditional training — shadowing, observation, bench simulations — and are looking for solutions that offer realistic operational experiences in high-risk contexts.

Why use virtual reality in laboratory training

Virtual reality (VR) is becoming a strategic tool in technical-scientific training.

Thanks to immersive simulations, it is possible to recreate complex environments and high-risk procedures, allowing users to practice without any biological or operational danger.

The main advantages of VR in scientific training

VR allows you to:

- reduce risks during training;

- standardize procedures precisely and reproducibly;

- improve laboratory safety with controlled scenarios;

- monitor and track performance through objective data;

- reduce training costs by eliminating material waste and repeated shadowing;

- offer scalable, customizable, and measurable training.

In VR, mistakes become part of the learning process: they can be repeated and analyzed without any impact on the real laboratory.

Case Study: IZS VR – Scientific Training Enters Virtual Reality

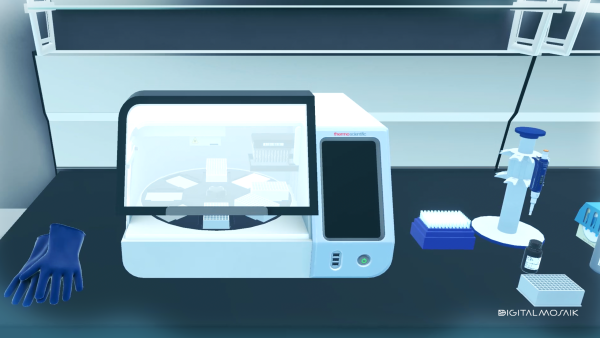

A concrete example of VR application in the scientific field is IZS VR, a project developed by Digital Mosaik for the Istituto Zooprofilattico Sperimentale dell’Abruzzo e del Molise “G. Caporale”.

Designed for the training of researchers and laboratory technicians, the system recreates the procedure for identifying the Rift Valley Fever virus in a three-dimensional virtual environment.

Users can practice every stage of the protocol completely safely:

- donning and using personal protective equipment (PPE);

- handling laboratory instruments;

- manipulating samples;

- responding to critical situations and emergencies.

The training pathway is divided into four main modules, available in two modes:

- Training — with visual and audio instructions, and guided support;

- Test — to assess the operator’s autonomy without hints.

Every action — movement, choice, or request for help — is tracked by an integrated Learning Management System (LMS).

The system assigns scores, provides personalized feedback, and allows for an objective measurement of the skills acquired.

From Simulation to Real Impact on Laboratory Safety

IZS VR demonstrates that virtual reality in scientific training is not just a technological innovation, but a true strategic asset.

Thanks to VR, research institutes can:

- improve laboratory safety levels;

- enhance the preparedness of technical and scientific staff;

- optimize learning times;

- ensure the quality and reproducibility of procedures.

In a sector where precision and safety are essential, virtual reality represents a concrete investment in skills, awareness, and the protection of operators.